أرسل لنا رسالة

dry processs portland cement preperation flow sheet

Manufacture Of Portland Cement Process Flow chart - civil

2019/11/30 Mixing of raw materials: The processes used for the manufacture of portland cement can be classified as dry and wet. In dry process. The raw materials are first reduced in

获取价格

Manufacture of Cement- Materials and Manufacturing

The manufacture procedures of Portland cement is described below. Mixing of raw material. Burning. Grinding. Storage and packaging. 1. Mixing of raw material. The major raw materials used in the manufacture of cement are

获取价格

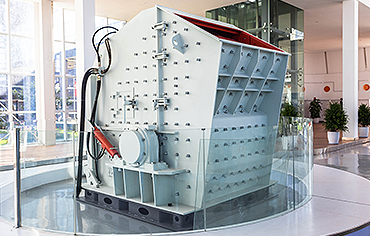

1: Simplified schematic flow chart of the dry process of

Download scientific diagram 1: Simplified schematic flow chart of the dry process of manufacturing of Portland cement (after (Johannesson, 2012)). from publication: Transport in concrete with ...

获取价格

Manufacturing of Cement By Dry and Wet Process

In this kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart. (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process. It is because the raw material in

获取价格

Chapter-5 Cement Processing Technology - eopcw

oxide (Fe2O3) - the raw materials of cement manufacture. Raw material preparation: To form a consistent product, ... Grinding may be a wet process or dry process and dry process is

获取价格

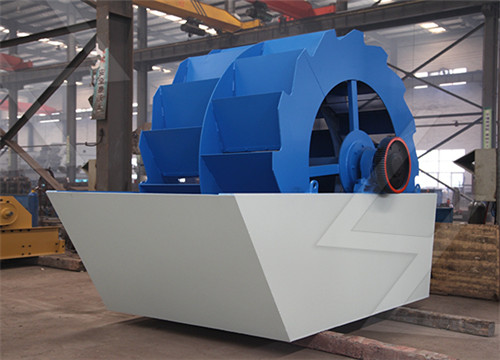

The Cement Production Flow Sheet By the dry process

The replacement of Portland cement is one way to reduce CO2. This research investigated the replacement of Portland cement (PC) by calcined clay (CC) and Limestone (LS). It was found that ...

获取价格

11.6 Portland Cement Manufacturing - US EPA

1971/8/17 A diagram of the process, which encompasses production of both portland and masonry cement, is shown in Figure 11.6-1. As shown in the figure, the process can be

获取价格

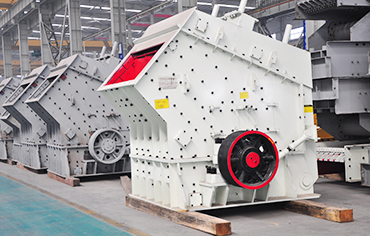

Typical cement manufacturing process flow diagram

The Cement Production Flow Sheet By the dry process [3] 3. Types of wastes generated from cement industry Solid Wastes:In cement manufacturing mainly, solid waste includes clinker production and ...

获取价格

Cement manufacturing process PPT Free Download

2014/6/10 Manufacturing of PORTLAND CEMENT. Components Processes Dry Process Wet Process. The document provides information on the process of determining the fineness of cement through dry sieving. It involves

获取价格

11.6 Portland Cement Manufacturing - U.S. Environmental

natural, masonry, and pozzolanic cement. The six-digit Source Classification Code (SCC) for portland cement plants with wet process kilns is 3-05-006, and the six-digit SCC for plants with dry process kilns is 3-05-007. Portland cement accounts for 95 percent of the hydraulic cement production in the United States.

获取价格

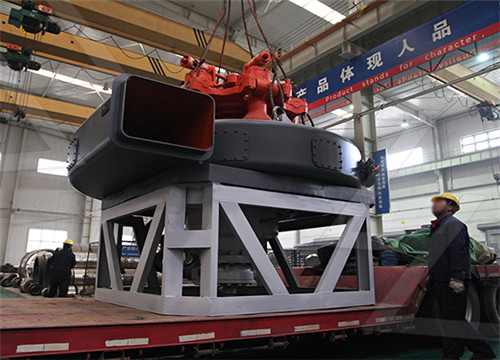

Aspen Plus process simulator flow sheet for a typical

Furthermore, in actual production, by mixing 100 tons of SS and FA with Portland cement with a daily output of 2500 tons, the compressive strength during early hydration stages can reach 34.52 MPa ...

获取价格

1: Simplified schematic flow chart of the dry

Download scientific diagram 1: Simplified schematic flow chart of the dry process of manufacturing of Portland cement (after (Johannesson, 2012)). from publication: Transport in concrete with ...

获取价格

11.6 Portland Cement Manufacturing - U.S. Environmental

natural, masonry, and pozzolanic cement. The six-digit Source Classification Code (SCC) for portland cement plants with wet process kilns is 3-05-006, and the six-digit SCC for plants with dry process kilns is 3-05-007. Portland cement accounts for 95 percent of the hydraulic cement production in the United States.

获取价格

Portland Cement Manufacturing process and flow sheet in Telugu

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright ...

获取价格

Cement manufacturing process PPT Free Download - SlideShare

2014/6/10 Evolution of the cement Process • Wet process easiest to control chemistry better for moist raw materials. • Wet process high fuel requirements - fuel needed to evaporate 30+% slurry water. • Dry process kilns less fuel requirements • Preheater/Precalciner further enhance fuel efficiency allow for high production rates.

获取价格

Dry Process for Manufacturing of Cement - GharPedia

2018/8/4 The clinker drops into coolers where it is cooled under control condition. Cooled clinker and 3 to 5 percent of gypsum are ground in ball mill to required fineness and then taken it to storage silos from where the cement is bagged. The equipments used in the dry process kiln are comparatively smaller. The process is quite economical.

获取价格

Production of cement Portland cement by flow sheet

观看视频11:212023/4/14 #chemiworld #cement #flowsheet #portlandcement #chemicalengineering tags production of cement,production of Portland cement,manufacture of cement in hindi,c...

获取价格

portland cement dry process flow sheet – Grinding Mill China

Chapter 1 – Introduction to Cement Production. Burning the blended materials is the key in the process of making cement.The wet or dry process of Portland cement Flow Chart Newer Manufacturing Process » Free online chat! Process flow sheets: Production Process of Mini Cement Plant. Jun 20, 2011 The dry process of cement production is resources

获取价格

sbm dry process of cement flow chart.md

Contribute to naicha22/2022 development by creating an account on GitHub.

获取价格

Step-by-Step Guide to the Manufacturing of Cement - PRACTICAL

The proportion of gypsum varies depending on the type of cement being produced; for Ordinary Portland Cement (OPC), it remains between 3 to 4%, and for Quick Setting Cement, it can be reduced to 2.5%. Purpose of Gypsum: Gypsum is added to regulate the setting time of cement. It slows down the hydration process, preventing the cement from ...

获取价格

Asbestos Cement Production Methods: asbestos cement

The Hatschek machine, a wet transfer roller, was used to produce the initial asbestos-cement sheets, while two other manufacturing processes included the Mazza process for pipes, and the Magnani semi-dry process for corrugated sheets. - Woods (2000) [Click to Enlarge any Image]

获取价格

Dry Process Of Cement Manufacturing - Dry Cement AGICO

The new dry-process cement production line technology was developed in the 1950s, so far, the new dry process cement equipment rate of Japan, Germany, and other developed countries have accounted for 95%. This cement production process regards the suspension preheating and pre decomposition as the core, and has the advantages of small pollution ...

获取价格

Emission Factor Documentation for AP-42 Portland Cement

cement plants with wet process kilns is 3-05-006, and the six-digit SCC for plants with dry process kilns is 3-05-007. 2.1 CHARACTERIZATION OF THE INDUSTRY 1-4

获取价格

Step-by-Step Guide to the Manufacturing of Cement

The proportion of gypsum varies depending on the type of cement being produced; for Ordinary Portland Cement (OPC), it remains between 3 to 4%, and for Quick Setting Cement, it can be reduced to 2.5%. Purpose of Gypsum:

获取价格

Asbestos Cement Production Methods: asbestos

The Hatschek machine, a wet transfer roller, was used to produce the initial asbestos-cement sheets, while two other manufacturing processes included the Mazza process for pipes, and the Magnani semi-dry process for corrugated

获取价格

Dry Process Of Cement Manufacturing - Dry Cement

The new dry-process cement production line technology was developed in the 1950s, so far, the new dry process cement equipment rate of Japan, Germany, and other developed countries have accounted for 95%. This cement

获取价格

Emission Factor Documentation for AP-42 Portland Cement

cement plants with wet process kilns is 3-05-006, and the six-digit SCC for plants with dry process kilns is 3-05-007. 2.1 CHARACTERIZATION OF THE INDUSTRY 1-4

获取价格

Simulation and Optimization of an Integrated Process Flow Sheet

2021/3/9 In this study the process flow diagram for the cement production was simulated using Aspen HYSYS 8.8 software to achieve high energy optimization and optimum cement flow rate by varying the flow ...

获取价格

Cement Production Process Cement Manufacturing Process AGICO CEMENT

2020/8/25 The Portland cement manufacturing process is representative of all types of cement. limestone and clay are the main raw materials of cement making, the cement raw materials will be processed into a raw meal by crushing, batching, grinding. ... Cement raw material preparation: ... The main advantage of dry process cement production is low heat ...

获取价格

11.6 Portland Cement Manufacturing - US EPA

Classification Code (SCC) for portland cement plants with wet process kilns is 3-05-006, and the six-digit SCC for plants with dry process kilns is 3-05-007. Portland cement accounts for 95 percent of the hydraulic cement production in the United States. The balance of domestic cement production is primarily masonry cement. Both of these

获取价格

A Look at Portland Cement: History, Composition, and Uses

2024/6/28 Portland cement is a versatile bonding agent composed of clinker compounds and calcium sulfate. The most common type of Portland cement, called ordinary Portland cement (OPC), is gray in color and widely used in the production of concrete, mortar, stucco, and non-specialty grout. It comes in five types, each with different properties and ...

获取价格

Portland Cement PDF Concrete - Scribd

5. Portland Cement - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses Portland cement, including its raw materials, production process, chemical composition, and hydration. Portland cement is produced by heating limestone, clay, and other materials in a kiln to form clinker, which is then

获取价格

Cement Manufacturing Process and Its Environmental Impact

The Cement Production Flow Sheet By the dry process [5] 3.1 Quarrying and Raw Material Preparation: In the quarrying process, raw materials such as limestone, clay, or shale are extracted

获取价格

Dry Process of Cement Manufacturing Semi-dry Process

2022/4/8 The main difference between the dry process and wet process of cement manufacture is the way in which the raw materials are prepared before they are fed into the kiln.. In the dry process, the raw materials are ground and dried into a powder, which is then mixed and fed into the kiln. The raw materials are heated to a temperature that causes them to react and

获取价格

Typical cement manufacturing process flow diagram [4].

The Cement Production Flow Sheet By the dry process [3] 3. Types of wastes generated from cement industry Solid Wastes:In cement manufacturing mainly, solid waste includes clinker production and ...

获取价格

Engineering Materials Portland Cement Difference Between Dry

This video explains comparison between Dry and wet process of mixing of Raw materials in manufacturing of cement.Link for Manufacture of cement by rotary kil...

获取价格

Dry - Set Portland Cement Mortar - SGM

Dry - Set Portland Cement Mortar. TECHNICAL DATA. APPLICABLE STANDARDS. ASTM International (ASTM) ANSI American National Standard Institute (ANSI) Conforms to requirements for dry set mortars found in ANSI A118.1, ANSI A108.5 specifications. When mixed with Southcrete 25 . Acrylic or Southcrete 28 Flexible Mortar Admix, conforms to ANSI

获取价格