أرسل لنا رسالة

crusher design parameters determined

Mathematical Modeling and Multi-Criteria

2023/5/17 Design diagram for determining the optimal profile of the crusher chambe Optimization of the parameters of the working chamber of a single-roll gyratory crusher (k 1 in m 3 /h).

获取价格

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

2017/6/30 Design of experiment techniques was used to determine the optimal design parameters. Optimisation results showed that the optimal design parameters were: 40.06 mm

获取价格

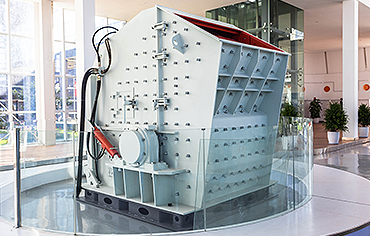

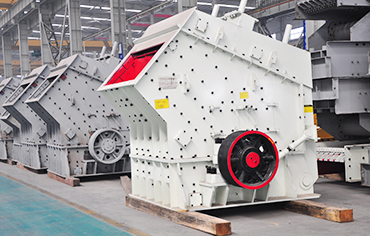

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT

Design Parameters 5 Chapter 2 Literature Study Performance model for impact crusher 6 Impact energy for crusher 9 ... Jaw crusher and Impact crusher. Our objective is to design various

获取价格

Mathematical Modeling and Multi-Criteria Optimization of Design

DESIGN AND ANALYSIS OF IMPACT CRUSHERS - National

Referring to fig. 1 an impact crusher is shown which comprises a housing. having disposed within a lower area of a rotor. mounted on a shaft. which is carried by suitable journal bearing. the

获取价格

DEM simulation of an impact crusher using the fast-cutting

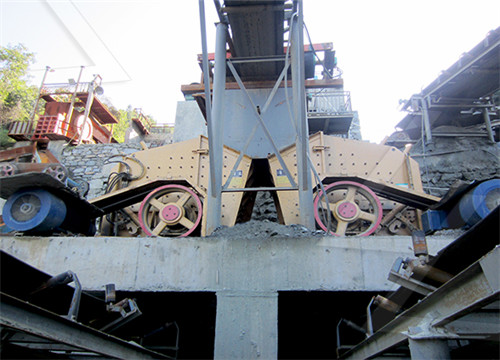

6 之 Crushing is a basic but important process widely encountered in the mineral industry. To adapt to different working conditions, many types of crushers have been designed, such as

获取价格

Optimizing processing parameters of stone crushers through

2022/1/1 The crushing parameters right from crusher speed, feed gradation to crusher settings not only affect the specific energy conversion of the crusher but also affect the

获取价格

Optimisation of the swinging jaw design for a single toggle jaw

2022/9/20 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the

获取价格

Geometric analysis of cone crusher liner shape: Geometric

2021/1/1 This simplicity also allowed the Whiten crusher model (Whiten, 1972) to describe jaw crusher performance with only three parameters – K1 which correlates with CSS, K2

获取价格

Study on Flow Pattern According to Rotor Design Parameter of

2020/3/31 In this study, design parameters are selected to determine the size of the rotor perpendicular plate hole. It is aimed to draw the hole size of the crusher rotor perpendicular plate that can minimize accumulation of the fuel inside the crusher cell by analyzing the fuel’s flow pattern according to the design parameters through flow analysis.

获取价格

A REVIEW ON STUDY OF JAW CRUSHER - 911 Metallurgist

Single toggle Jaw Crusher Design, College of Mechanical Engineering, Taiyuan University of Technology, Taiyuan, China.Jaw crusher is a kind of size reduction machine which is widely used in the mining and aggregates industry. The interaction between jaw

获取价格

Design and Calculation of Parameters of Jaw Crusher

The users of the jaw crusher must have deep understanding of the data to avoid the impropriate use which will cause abnormal production. The maximum feed size of the jaw crusher is determined by the conditions to snap the materials of the crusher. The width of the material inlet of China jaw crusher can be calculated by certain formula.

获取价格

m/sbm jaw crusher design parameters.md at main legaojm/m

Contribute to legaojm/m development by creating an account on GitHub.

获取价格

/sbm crusher design parameters determined.md at

You've already forked 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

获取价格

DESIGN AND DEVELOPMENT OF AN ERGONOMIC AND

So, we decided to design thecan crusher with mechanism which is very simple and require less force to crush. And can crusher also must be simple in design so that everybody can use it. ... A sample calculation is done after assumingsome parameters after fabrication of project. Force required to crush can: For this project (Cancrusher)

获取价格

Design Improvement and Computer Modeling of the Finger Grain Crusher

2024/7/6 The analysis of literary sources showed that the following types of machines could be used for crushing grain mass: millstones [], roller machines [], flattening machines [], and roller crushers [], but hammer-type crushers became the most common [].In turn, hammer crushers can be divided into sieve hammer crushers with an axial feed [], open-type hammer

获取价格

DESIGN, FABRICATION AND TESTING OF A LABORATORY

fabricated machine with those of a standard Denver laboratory jaw crusher shows that the crushing rate of the new machine is higher, though the standard machine produces coarse ... some other parameters are the main factors considered before design of the machine. Theoretical Design Consideration The design was carried out on the basics of the ...

获取价格

Development of the parameters of crusher methods the

the parameters of the body of a fixed jaw crusher Kostiantyn Zabolotnyi1,*, and Olena Panchenko1 1National Technical University Dnipro Polytechnic, 49005, Dnipro, Yavornytskoho Ave., 19, Ukraine Abstract. By the example of justification of the design parameters of the fixed jaw body of the jaw crusher, the methods have been developed for

获取价格

DESIGN OF CRUSHER MACHINE FOR PLASTIC WASTE

Jaw Crushers have found their extensive application for the mid crushing of the various ores and large-size materials block in the field of mining, smelting, building material, highway, railway, water conservancy and chemical industry, etc. (Balasubramanian, 2017) Figure 2.1 Jaw crusher 2.4.2 Gyratory crusher A gyratory crusher is similar in ...

获取价格

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014/9/1 Rose and English determined the capacity of a jaw crusher by considering the time taken and the distance travelled by particles between the two plates while subjected to repeated crushing forces between the jaws [4]. The geometry parameters of the Rose and English design are given in Fig. 2.

获取价格

Chamber Optimization for Comprehensive Improvement of Cone Crusher

2021/3/15 The objective function was determined by studying the performance of the cone crusher. The design variables were determined by analyzing the structure parameters and process parameters of the cone crusher. The constraint conditions were set by combining the parameters of the cone crusher C900.

获取价格

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022/9/20 Design of experiment techniques was used to determine the optimal design parameters. Optimisation results showed that the optimal design parameters were: 40.06 mm thickness, 4.94 mm plate profile ...

获取价格

Improvement of Jaw Crusher Design by DEM FEA Approach

Crushing Pressure created by jaw crusher depends on design parameters such as; drive shaft eccentricity distance, toggle plate position, drive shaft revolution speed etc. In this study, Discrete Element Method (DEM) and Finite Element Analysis (FEA) ... In order to determine positions of the joints, kinematic analysis was performed. Eccentric ...

获取价格

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014/9/1 Rose and English determined the capacity of a jaw crusher by considering the time taken and the distance travelled by particles between the two plates while subjected to repeated crushing forces between the jaws [4]. The geometry parameters of the Rose and English design are given in Fig. 2.

获取价格

Chamber Optimization for Comprehensive Improvement of Cone Crusher

2021/3/15 The objective function was determined by studying the performance of the cone crusher. The design variables were determined by analyzing the structure parameters and process parameters of the cone crusher. The constraint conditions were set by combining the parameters of the cone crusher C900.

获取价格

Optimisation of the swinging jaw design for a single

2022/9/20 Design of experiment techniques was used to determine the optimal design parameters. Optimisation results showed that the optimal design parameters were: 40.06 mm thickness, 4.94 mm plate profile ...

获取价格

Improvement of Jaw Crusher Design by DEM FEA Approach

Crushing Pressure created by jaw crusher depends on design parameters such as; drive shaft eccentricity distance, toggle plate position, drive shaft revolution speed etc. In this study, Discrete Element Method (DEM) and Finite Element Analysis (FEA) ... In order to determine positions of the joints, kinematic analysis was performed. Eccentric ...

获取价格

Design of the crusher for plastic and rubber waste produced in ...

The basic parameters of the crusher were investigated for a determined final cutting force. Based on the cutting force and the designed crusher, a finite element analysis (FEM) was performed confirming the correctness of the selected material for the production of the crusher for the processing waste materials. ... The shaft diameter was ...

获取价格

Optimization of Jaw Crusher - Bonfring

improve the performance of a jaw crusher, is mainly determined by the kinematic features of the liner to optimize the frame, design the chamber and recognizing the crushing ... The parameter which most controls the design of the swing plate is the load distribution. Instrumentation of toggle arms in has since led to correlation

获取价格

(PDF) Design and Operations Challenges of a Single Toggle Jaw Crusher

Also, the horsepower being the amount of power consumed is a function of stroke, crushing force and eccentric speed; hence, conventional crusher design theory dictates that: Horsepower crushing force stroke R M According to More and Rajpal [31], Ashok and Yan gave the following models for the design of crusher jaws: Width (W) of jaw plate lies ...

获取价格

Design capacity calculation of hammer crusher

30 May 2023; The design capacity calculation of a hammer crusher involves determining the maximum capacity or throughput of the crusher based on the physical properties of the material being crushed and the operating parameters of the machine. Here’s a step-by-step guide to calculating the design capacity of a hammer crusher: Identify the material properties:

获取价格

Novel Design of a Modular Multi-stage Crusher with Adaptive

2022/3/16 The rest of this paper is as follows: Sect. 66.2 proposes a contradiction matrix based on TRIZ and actual parameter requirements and obtains the final required model through the principle of the invention, completed the innovative design process; Sect. 66.3 gives the System design process of the modular gap adjustable multi-stage crusher ...

获取价格

Design and Development of Can Crushing Machine - ResearchGate

2020/5/5 Mathematical modeling and optimization of the design parameters of the working chamber and the executive body (roll) of a single-roll gyratory shaft crusher, designed for crushing strong rocks ...

获取价格

Crusher Dynamics, Design and Performance - 911 Metallurgist

What is the most important crusher parameter? A. Closed Side Setting B. Feeding C. Chamber selection D. Capacity E. Eccentric speed. Background ... Cone Crushers The cone crusher design concept is an effective and smart way of realizing compressive crushing Why cone crushers? Mechanical mineral liberation - mining

获取价格

COLLEGE OF ARCHITECTURE AND ENGINEERING SCHOOL OF

are made to design a flywheel to minimize the wastage of power and to improvise the performance parameters of single toggle jaw crusher. Jaw plate wear has considerable effect on the life of jaw Crusher which is caused by the slipping motion between the fed material and the jaws. This wear is predominantly serious in the fixed

获取价格

Design and Fabrication of Aluminium Tin Can Crusher

2017/7/6 Design of recycle bin tin can crusher Can feed mechanism 2008 3. SYSTEM DESIGN total weight of machine and a lDesign consists of application of scientific principles, technical information and imagination for development of new or improvised machine or mechanism to perform a specific function with ...

获取价格

Novel design modeling for vertical shaft impactors

2024/1/15 1. Introduction. Vertical shaft impact crushers (VSI's) are usually used in tertiary crushing stations in both the aggregate and mining industries for crushing hard rock material or ores when a product material with a cubical shape and a number of fines is required [1, 2].A VSI crusher has also been shown to be one of the best options in comparison to other secondary

获取价格