أرسل لنا رسالة

crusher princible

Types of Crushers Explained: Everything You Need to

2024/4/19 All types of crushers have their own distinctive design, working principles, and applications. Cone Crushers. Cone crushers are usually applied in the secondary and tertiary crushing. They also play a role in reducing the size

标记:CrusherPrinciplesCrushing Principles of Mechanical Crushing - 911 Metallurgist

Crusher Operation. • Relation between Feed size and Shape. – The greater reduction ratio the worse particle shape. – Inter particle breakage improves shape. When crushing a bed of

标记:CrusherPrinciplesCrushing - Principles of Mechanical Crushing - 911 Metallurgist

Crusher Capacity: 300 tph . Choke fed Crusher operation(300 tph): Material in surge bin runs out at even intervals . Consequence: Crusher is operated choke fed 66% of total operating time

标记:CrusherPrinciplesWhat Is A Jaw Crusher - MEKA

The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws. The moving

标记:Jaw CrushersFunction of Jaw CrusherMining EquipmentMining EngineeringCrusher Principle PDF - Scribd

Crusher Principle - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. The document discusses different types of crushers including hammer mills, jaw

标记:Jaw CrushersHammer MillsTypes of Jaw CrusherWorking Principle of Crushers - 911Metallurgist

2016/2/18 Working Principle of Crushers. On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber

标记:CrusherCrushingUnderstanding the Cone Crusher Working Principle:

2023/2/23 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces. But how does it work? In this article, we'll explore the cone crusher working principle, including

标记:CrusherConePrimary Crusher vs. Secondary Crusher: Understanding

2023/2/28 A primary crusher is a machine that breaks down large rocks and stones into smaller particles for further processing. It is the first stage in the crushing process and is essential in the mining and construction industry. The

标记:CrusherCrushingHow it Works: Crushers, Grinding Mills and Pulverizers

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl

Working Principle And Application Exploration Of Vertical Shaft

2024/9/25 Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants.We can offer you a free design and completed solutions according to your project. Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating RD, manufacturing, sales,

Jaw Crusher Working Principle - StudiousGuy

A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws results in the development of compression force that further causes the breakdown of

Jaw crusher PPT - SlideShare

2014/12/9 • Working Principle Of A Jaw Crusher • A jaw crusher uses compressive force for breaking of particle. • A Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the ...

Zenith HPT Cone Crusher Working Principle - YouTube

观看视频0:382021/5/10 More details about hpt cone crusher: https://m.zenithcrusher/products/crusher/cone-crusher/hpt-series-cone-crusher.html?snsyoutube=zytWhen the HPT Hydrau...

ZENITH MINERALYou Should Know About the Jaw Crusher's Working Principle

2024/10/25 The jaw crusher machine we produce adopts the classic crushing principle of the interaction between the movable jaw and the fixed jaw, which can easily handle materials of various hardness. The unique design of jaw crusher machine not only improves the crushing ratio, but also ensures a better finished particle shape.

Understanding the Cone Crusher Working Principle: How It

2023/2/23 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces. But how does it work? In this article, we'll explore the cone crusher working principle, including the eccentric motion of the main shaft, the crushing process, and the importance of proper maintenance. Whether you're a seasoned

What Is A Jaw Crusher - MEKA

The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws. The moving jaw moves back and forward against the fixed jaw, and material fed from the top of the machine is compressed ...

Crusher and Its Types PDF - SlideShare

2019/1/10 The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening. The crushing power of the jaw crushers depends on the size of the chamber.

Jaw Crusher Working Principle - 911Metallurgist

2021/5/6 A sectional view of the single-toggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point. The motion is, however, a more complex one than the Dodge motion, being

CRUSHERS.pdf Free Download - SlideShare

2022/11/23 PRINCIPLE OF JAW CRUSHER •This jaw crusher uses motor as its power. •Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. •Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can ...

jaw crusher working principle!Direct truck unloding # ... - YouTube

jaw crusher working principle!Direct🔥truck unloding #rockcrusher #jawcrusher@Crusharvilog "Learn how jaw crushers work! Watch as we unload a truck directly ...

Crushing Principles of Mechanical Crushing - 911 Metallurgist

This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain. Over crushing is common. The connection between crusher setting and yield is often unknown The rock cannot be repaired. We need to control the crusher carefully.

Comprehensive large wood crusher working principle, 3D

Comprehensive large wood crusher working principle, 3D animation demonstration

CRUSHERS.pdf Free Download - SlideShare

2022/11/23 PRINCIPLE OF JAW CRUSHER •This jaw crusher uses motor as its power. •Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a

jaw crusher working principle!Direct truck unloding # ... - YouTube

观看视频9:574 之 jaw crusher working principle!Direct🔥truck unloding #rockcrusher #jawcrusher@Crusharvilog "Learn how jaw crushers work! Watch as we unload a truck directly ...

Jaw Crusher vilogCrushing Principles of Mechanical Crushing - 911 Metallurgist

This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain. Over crushing is common. The connection between crusher setting and yield is often unknown The rock cannot be repaired. We need to control the crusher carefully.

Comprehensive large wood crusher working principle, 3D

观看视频0:112024/11/4 Comprehensive large wood crusher working principle, 3D animation demonstration

gaoqiang geCrushing - Principles of Mechanical Crushing - 911

Crusher Capacity: 300 tph . Choke fed Crusher operation(300 tph): Material in surge bin runs out at even intervals . Consequence: Crusher is operated choke fed 66% of total operating time feeding the screen with 300 tph . Screen overload . Solution: Adjust throw in order to reach 200 tph capacity . 32 200 200 200 66% Capacity utilization 300 300

How Does a Jaw Crusher Work - Kemper Equipment

A jaw crusher is an important piece of machinery that helps break aggregate material down into the right size. Learn more about this machine on our blog today. ... These design tweaks over time have perfected a machine that’s simple enough in its working principle that it may never truly become obsolete. Today, two main jaw crusher ...

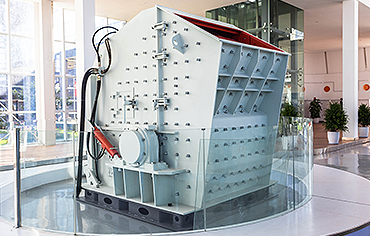

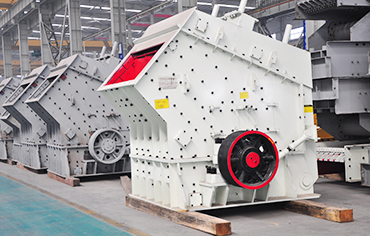

Impact Crusher working principle parts and maintenance

Unlike other crushing machines like jaw crushers or cone crushers, which apply pressure to break the material, an impact crusher uses rapid collisions between the hammer and the target material. Impact crushers are designed with heavy-duty rotors that rotate at high speeds, allowing them to deliver tremendous force when striking the material.

What is the working principle of the 420 small wood crusher

2024/5/10 The working principle of the 420 small wood crusher mainly relies on the synergistic effect of its internal mechanical structure and power system. The following is a detailed explanation: dynamical system. Electric motor or diesel engine: 420 small wood crushers usually use electric motors or diesel engines as power sources.

mobile crusher principle Crusher, Conveyor, Construction waste

Crawler-Type Mobile Crusher - Eastman Rock Crusher Crawler type mobile crushers are designed for unfixed mining, quarrying, construction sites, highly customized with crushers, screen, feeder, conveyor, etc.

crusher/sbm jaw crusher working princible.md at master - crusher ...

You've already forked crusher 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Impact Crusher Working Principle/How Impact Crusher Crushes

Impact crusher working principle: Use impact energy to crush material when the material enters the working area of the plate hammer,firstly crushed by the im...

Jaw Crusher: Range, Working Principle, Application -

Jaw Crusher Working Principle. A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism. The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller ...

Hammer Crusher Working Principle - AGICO Cement Plant

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining