أرسل لنا رسالة

plant design batch leaching of gold

The process design of gold leaching and carbon-in-pulp circuits

This is done by contacting the carbon with a solution of sodium cyanide. (0.1 to 2% by mass) and sodium hydroxide (0.1 to 2% by mass) at high temperatures (90–120°C). This results in the

获取价格

Design of a Combined Gravity Concentration and Leaching

box and a leaching plant to improve gold recovery. 2 Design Optimization and Operation The optimized design combines a cyanide-based leaching system to the operation of a multiple

获取价格

Intensive cyanidation: onsite application of the InLine Leach

3.6. Batch InLine Leach Reactor operation The concentrates from the primary recovery device report to the feed cone for de-watering, with the water overflowing and returning to the mill

获取价格

CIP/CIL Modelling - AusIMM

The SGS carbon-in-pulp (CIP) / carbon-in-leach (CIL) modelling packaged is used to: Estimate the performance of a full-scale CIP and CIL plant. Derive the optimum design criteria based on

获取价格

Estimating process design gold extraction, leach residence

Plant design scale-up considerations For the design of commercial-scale gold cyanidation operations, gold recovery, leach residence time and cyanide consumption are generally

获取价格

Factors influencing the rate of gold cyanide leaching and

2011/5/1 Worldwide gold recovery on activated carbon grew from zero to almost 70% in twenty years from 1980. The stellar attributes of carbon gold plants led to complacency in the

获取价格

Leaching Plant Design - 911Metallurgist

2016/5/24 Modern Leaching Plant Design. Importance of Laboratory Testing to Leaching Plant Design. Leaching plants, faced with increased tonnage, coarse (up to —3/16″ solids) feed, longer retention time, erosion, corrosion

获取价格

VAT LEACHING AND ELUTION PLANT - GOLD

A direct smeltable gold concentrate is produced as well as a lower grade concentrate for future intensive leaching or sale. Both plants were designed and built within very tight time frames and budgetary constraints. The experience

获取价格

Estimating process design gold extraction, leach residence time

2015/5/1 Plant design parameters for gold extraction, leach residence time and cyanide consumption are generally determined from standard bench-scale bottle roll or agitation leach

获取价格

Gold Extraction Process Development - alsglobal

ores including batch leaching tests to determine the effect of grind size, pH, cyanide solution strength, influence of dissolved oxygen concentration, influence of leach accelerants (such as

获取价格

Insights From Simulation of a CIL/CIP Circuit - 911

In a batch leaching situation: T ()T Frem f e f e = . −α + 1− . −β (1) where Frem is the fraction of silver or gold remaining unleached, f is the fraction of the gold or silver which is fast leaching, T is the time of leaching and α and β are the leaching rates of the fast and slow components (reciprocal time).

获取价格

sbm/sbm crushing plant design batch leaching of gold

Contribute to jgw2023/sbm development by creating an account on GitHub.

获取价格

Gold and Silver Leaching by Cyanidation

2016/4/18 The cyanide leaching process is the most important method ever developed for extracting gold from its ores. The early development of the process is attributed 911 Metallurgist is a trusted resource for practical

获取价格

Gold Extraction Process Development - alsglobal

minerals present in gold ores is required to successfully design and operate a gold extraction process for optimum efficiency. ... ores including batch leaching tests to determine the effect of ... and leach time can be performed. Tests can be on samples from 0.50kg up to 2000kg. Plant design data generation such as slurry rheology measurements ...

获取价格

CIP/CIL Modelling - AusIMM

plant design may be “less-than-optimum” because: ... density in small scale batch test. Fit adsorption data to adsorption equation ... Gold leaching kinetics (and leach rate constant); Conditions: 10kg, 72h, 50% w/w, 0.5g/L cyanide, pH 10.5 Carbon Adsorption kinetics from leached slurry (plant regen carbon)

获取价格

(PDF) Factors influencing the rate of gold cyanide leaching and ...

2011/5/1 In the cyanide leaching tests, those performed at a high cyanide level (i.e., 5 g/L) produced high gold and silver extractions from the roasted ore apparently due to the increased availability of ...

获取价格

plant design-batch leaching of gold – Grinding Mill China

Gulin Least News. Optimizing manganese ore sinter plants: process parameters and design implications » The More » 50 inch raymond roller mill » advanced material in civil eng ppt » advance of mechanical engineering projects of fabrication » 1.25 ltr table top wet grinders in india price » a list of aluminium extrusion factory india Contact Us. Tel: 86-21-58386256

获取价格

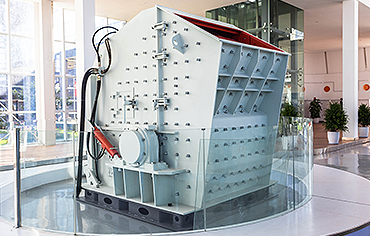

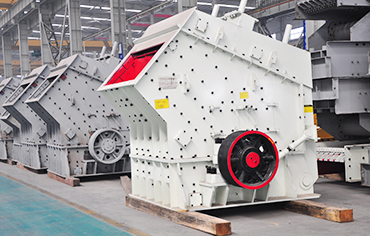

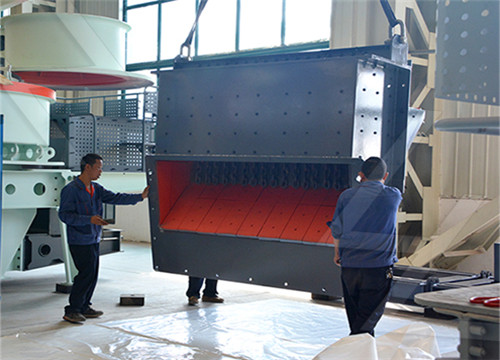

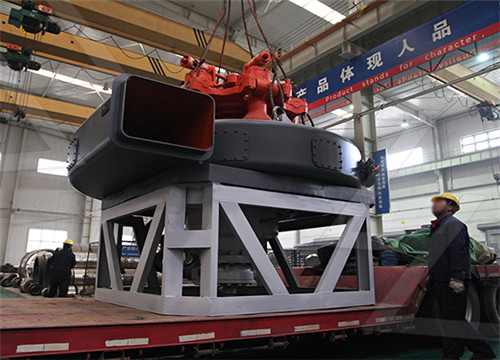

Small Scale Modular Batch Leaching Plant GOLD PROCESSING

The modular batch leaching plant recovers gold from concentrate and high-grade ore. Concentrate produced by flotation and/or gravity concentration and high-grade ore are collected to process together. ... BUSINESS SCOPE EPC Metallurgical Test Engineering Design Equipment and Facilities Manufacture Packing and Transportation Installation ...

获取价格

Autoclave Design and Scale-Up - 911Metallurgist

2017/10/7 Commercial pressure leaching autoclaves have been in operation since mid 1950s. Historical production data suggest that these early autoclaves were originally designed with excess capacity (Berezowsky, Collins, Kerfoot, and Torres, 1991). Process development initially consisted of tests in batch autoclaves.

获取价格

Factors influencing the rate of gold cyanide leaching and adsorption

2011/5/1 Worldwide gold recovery on activated carbon grew from zero to almost 70% in twenty years from 1980. The stellar attributes of carbon gold plants led to complacency in the industry in designing and operating these plants. Most CIP and CIL plants are overdesigned and operated sub-optimally. Optimum design criteria and operating conditions are easily

获取价格

Vat Leaching of Finely Crushed Gold Ore - 911Metallurgist

2016/7/13 The ore, confined in a rectangular leaching vat is successively treated with an increasing concentration of leach solution, which may be added as a continuous flow or on a batch basis. Thus, maximum leaching strength first comes in contact with minimum metal concentration in the ore, and as its leaching potential diminishes, it comes in contact ...

获取价格

MERRILL CROWE IN LEACHING GOLD / SILVER PROCESSING

Gravity Recovery Au/Ag Leaching – CCD Merrill Crowe Plant Refinery: This complete hydrometallurgical process plant is for recovering precious metal from oxide or very low sulphide ore deposits containing silver and/or gold more commonly.The turnkey plant is for the recovery by cyanidation leaching from ores absent of preg-robbing carbonaceous material.

获取价格

Increase Dissolved Oxygen in Gold Leaching with Hydrogen

2017/12/27 Figure 1 shows the pilot plant used for the small-scale testwork. Precious metals like gold and silver are normally extracted by converting them into soluble cyanocomplexes. Since the ores usually contain the gold and sometimes the silver in its elementary form, an oxidant is needed to bring about the dissolution of the precious metals.

获取价格

Estimating process design gold extraction, leach residence time

An official publication of the Society for Mining, Metallurgy Exploration Inc. Key words: Process design, Gold extraction, Leach residence time, Cyanide consumption, Cyanide leaching, Cyanidation, Carbon-in-leach, Carbon-in-pulp Introduction Major factors in the design of a gold processing plant are gold recovery, leach residence time and ...

获取价格

Vat Leaching of Finely Crushed Gold Ore

2016/7/13 The ore, confined in a rectangular leaching vat is successively treated with an increasing concentration of leach solution, which may be added as a continuous flow or on a batch basis. Thus, maximum leaching strength first

获取价格

MERRILL CROWE IN LEACHING GOLD / SILVER

Gravity Recovery Au/Ag Leaching – CCD Merrill Crowe Plant Refinery: This complete hydrometallurgical process plant is for recovering precious metal from oxide or very low sulphide ore deposits containing silver and/or gold more

获取价格

Increase Dissolved Oxygen in Gold Leaching with Hydrogen

2017/12/27 Figure 1 shows the pilot plant used for the small-scale testwork. Precious metals like gold and silver are normally extracted by converting them into soluble cyanocomplexes. Since the ores usually contain the gold and sometimes the silver in its elementary form, an oxidant is needed to bring about the dissolution of the precious metals.

获取价格

Estimating process design gold extraction, leach residence time

An official publication of the Society for Mining, Metallurgy Exploration Inc. Key words: Process design, Gold extraction, Leach residence time, Cyanide consumption, Cyanide leaching, Cyanidation, Carbon-in-leach, Carbon-in-pulp Introduction Major factors in the design of a gold processing plant are gold recovery, leach residence time and ...

获取价格

Gold CIL CIP Gold Leaching Process Explained CCD

2013/1/3 Counter-current leaching. leaching efficiency can be enhanced by the application of Le Chatelier’s principle. In summary, the lower the concentration of gold in solution, the greater the driving force for gold dissolution to occur, although in a mass transport controlled reaction it is debatable what role this plays in gold leaching.

获取价格

Intensive cyanidation: onsite application of the InLine Leach

2003/5/1 The Batch Inline Leach Reactor enables gold operations to significantly increase the amount of gold recovered from gravity. ... 2002. New age gold plant flowsheet for the treatment of high grade ores. In: AusIMM––Metallurgical Plant Design and Operating Strategies Conference, Sydney. Google Scholar. McQuiston, 1985. F.W. McQuiston Jr. N.L ...

获取价格

(PDF) Factors influencing the rate of gold cyanide leaching and ...

2010/6/10 performance of gold plants, and optimize CIP or CIL plant design, is to conduct inexpensive bench scale metallurgical tests to exam- ine the rheological properties of a leach pulp early in the ...

获取价格

Unity Mining - Henty Gold Mine - Process Plant - Leaching the gold

观看视频1:342015/5/1 A short video of Henty Gold Mine's processing plant showing how the leaching process extracts the gold

获取价格

Estimating process design gold extraction, leach residence

2015/5/1 Plant design parameters for gold extraction, leach residence time and cyanide consumption are generally determined from standard bench-scale bottle roll or agitation leach tests.

获取价格

Cyanide Processing Equipment and Plant Configuration Options

2016/3/15 The Jig, placed between the ball mill and classifier, is one of the most valuable and affordable improvements in cyanidation in recent years and was developed by the metallurgical engineering and Mining Equipment Companies.. This Mineral Jig has the marked advantage of removing a large portion of the metallic values without excessive dilution, and

获取价格

Gold Metallurgy Leaching in Cyanicides - 911Metallurgist

2016/7/14 Cyanidation as applied to ordinary gold and silver ores is a relatively simple process. When cyanicides {cyanide-consuming elements) are encountered in small amounts in the treatment of such ores, the various schemes already discussed, such as use of a lead salt or wasting barren solution, can usually be resorted to and successful operation maintained.

获取价格

Small Scale Modular Gold Batch Leaching Plant

Small Scale Modular Gold Batch Leaching Plant, Find Details and Price about Gold Mining Equipment Gold Mine Equipment from Small Scale Modular Gold Batch Leaching Plant - Yantai Huize Mining Engineering Co., Ltd. ... HZE is a company with RD center, design institute, manufacturing factories, installation and commissioning teams. Our customers ...

获取价格

Advances in Gravity Gold Technology - ScienceDirect

2016/1/1 Gravity separation has been utilized in gold plants as the primary recovery mechanism or alternatively ahead of other downstream processes such as flotation and cyanidation since the inception of mineral processing. ... The batch InLine Leach Reactor ... (Eds.), Mineral Processing Plant Design, Practice, and Control Proceedings, Society of ...

获取价格

The process design of gold leaching and carbon-in-pulp

the size of the leaching plant that would be required as well as reduces the amount of leaching reagents required. Many gold plants use conventional thickening with flocculant addition. High rate thickeners, as well as de-watering systems that use cyclones only or cyclones and high-rate thickeners can also be used in principle.

获取价格