أرسل لنا رسالة

Sinter processing equipment process flow

Understanding Sinter and Sinter Plant Operations

2015/3/15 Return fines, not suitable for downstream processing, are conveyed to a bin for recycling in the sintering process. Use of sized sinter is desirable for the improvement of production rates in the blast furnace. Further,

获取价格

Automatic loading and unloading complete equipment process

The invention relates to a powder material sintering processing equipment process, in particular to an automatic loading and unloading complete equipment process flow for powder sintering

获取价格

Typical process flow sheet for sinter machines

However, during the process of absorption, the manganese dioxide in the pyrolusite was converted to dithionate [10], bringing pollution to the subsequent processing. The fuel gas of the sintering ...

获取价格

Model of an iron ore sinter plant with selective waste gas ...

2022/3/1 Sintering of iron ores is an enormous energy-intensive and resources consuming process. Introducing a selective waste gas recirculation (SWGR) to the sintering process

获取价格

Iron Ore Sintering - SpringerLink

2024/1/1 Iron ore sintering is the iron ore powder agglomeration process that changes fine iron ore powder into the lumpy iron-bearing raw material used for blast furnace ironmaking.

获取价格

Flow chart of all sintering and sintering processes.

Download scientific diagram Flow chart of all sintering and sintering processes. from publication: The evaluation of different environments in ultra-high frequency induction sintered powder ...

获取价格

Sintering Process - an overview ScienceDirect Topics

14th International Symposium on Process Systems Engineering. Haoran Li, Tong Qiu, in Computer Aided Chemical Engineering, 2022. 2.1 Process description. The sintering process

获取价格

(PDF) Iron Ore Sintering: Process - ResearchGate

2017/2/16 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slag-forming agents and solid fuel (coke). The purpose of the ...

获取价格

Sintering - Eurotherm

Figure 1 shows a simplified diagram of a sinter plant. Materials enter the sinter plant from storage bins. They are mixed in the correct proportions using weigh hoppers, one per storage bin, except for the return fines for which an impact

获取价格

Latest Generation Sinter Process Optimization Systems

Data handling encompasses the chemical and physic al data of the sinter strand as well as the process history. The raw sinter mix and the production process is monitored in detail from ore

获取价格

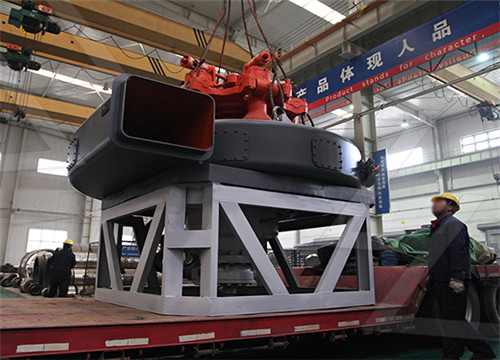

Sinter Plant Design, Engineering, Construction M HEAVY

A Sinter plant in a steel plant is the final operation in a series of measures to prepare iron ore for blast furnace smelting.A sinter plant is an enterprise with a complicated technological process for producing the final product – agglomerate or sinter.. Agglomeration is a process of sintering fine ores and concentrates by fuel combustion in a layer of sintered material.

获取价格

Application of deep learning in iron ore sintering process: a

2024/3/16 The sintering process is an intricate system with a protracted process flow. The steps in the manufacturing line are primarily composed of the ingredients and mixing process, the sintering operation process, and the treatment of the sintered ore [39, 40].2.2 Important parameters and characteristics of sintering process. As shown in Fig. 2, all variables affecting

获取价格

System dynamics analysis on characteristics of iron-flow in sintering ...

2015/5/5 The effects of returned iron-flow on the dynamic characteristics of iron-flow in sintering process are also studied. The results can provide some guidelines to recognize the dynamic characteristics of the iron-flow in sintering process, to improve the utilization efficiency of iron resource and to optimize the process operation. 2.

获取价格

(PDF) Iron Ore Sintering: Process - ResearchGate

2017/2/16 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slag-forming agents and solid fuel (coke).

获取价格

On the Use of Metal Sinter Powder in Laser Powder Bed Fusion Processing

The work sets an incentive for further research in the area of best cost concepts in PBF-LB/M, as well as in the processing of coarse-grained sinter powders in the PBF-LB/M process. From the observations, the following conclusions are drawn regarding the use of a multimode rather than a single-mode fiber laser, each supported by findings from ...

获取价格

Industrial Experience of New Sinter Hydro-chemical Processing Process ...

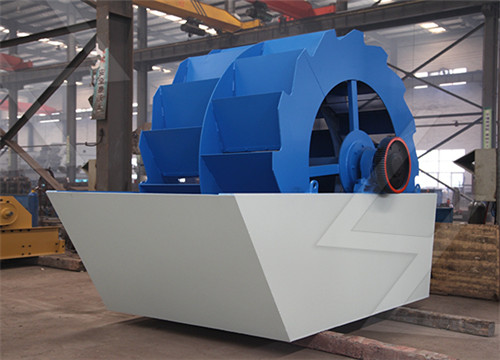

2018/2/2 Schematic of the test flow sheet. ... Processing of sinter is planned in a newly built building with process equipment—conveyor, hoppers, sinter feeders, ball mills, sinter slurry mixers, the pump yard and other equipment. ... On the basis of industrial trials and the proposed process flowsheet of sinter processing a financial and economic ...

获取价格

One-step synthesis and low-temperature rapid sintering of

2024/3/1 The alumina-zirconia amorphous precursor powder was used to replace the final product powder for ceramic processing, and the one-step synthesis and rapid sintering densification of alumina-zirconia ceramics at low temperature of 849 °C for 60 s were realized. ... these methods require huge and expensive sintering equipment, which increases ...

获取价格

Numerical Simulation of Hot Isostatic Pressing Process ... - Springer

2019/4/24 As the process involves unsteady flow through porous felt as well as graphite cylinders, transient analysis of argon flow inside the horizontal vacuum sintering furnace is simulated. The argon gas is passed into the furnace through an

获取价格

Filler metal control in sinter brazing - Thermal Processing

2018/5/15 The time for a filler metal to flow into a clean, properly designed braze joint and form a good braze is three to five minutes at the brazing temperature that is above the liquidous temperature of the filler metal. ... in or near the adjoining surfaces of the shapes to allow for brazing to occur simultaneously with the powder metal sintering ...

获取价格

Silicon carbide manufacturing process - GAB Neumann

Silicon carbide for process equipment applications is manufactured by the sintering process. ... During the sintering process, and more precisely between approximately 1900°C (3450°F) and 2150°C (3900°F), the products shrink isostatically by a factor of roughly 20%. The block height, diameter and hole diameters all shrink by roughly 20% ...

获取价格

Sintering - Eurotherm

Figure 1 shows a simplified diagram of a sinter plant. Materials enter the sinter plant from storage bins. They are mixed in the correct proportions using weigh hoppers, one per storage bin, except for the return fines for which an impact meter is used instead. Weighing is continuous, as is the whole sintering process.

获取价格

Simulation of gas–solid flow in sinter vertical cooling furnace

2023/5/28 The velocity distribution of sinter and gas in vertical cooling furnace (VCF) has an important influence on gas–solid heat transfer. Based on the slot model of single hopper in the VCF of ...

获取价格

Iron Ore Sintering - SpringerLink

2023/6/8 Modern sintering process consists of three stages: sintering raw material preparation, sintering, and sinter processing (Fig. 1).Sintering raw material preparation stage consists of the steps such as uniform mixing of raw material in storage, and processing, batching, mixing, granulation, and distribution of flux and fuel.

获取价格

Sintering - Eurotherm

Figure 1 shows a simplified diagram of a sinter plant. Materials enter the sinter plant from storage bins. They are mixed in the correct proportions using weigh hoppers, one per storage bin, except for the return fines for which an impact

获取价格

Simulation of gas–solid flow in sinter vertical cooling

2023/5/28 The velocity distribution of sinter and gas in vertical cooling furnace (VCF) has an important influence on gas–solid heat transfer. Based on the slot model of single hopper in the VCF of ...

获取价格

Iron Ore Sintering - SpringerLink

2023/6/8 Modern sintering process consists of three stages: sintering raw material preparation, sintering, and sinter processing (Fig. 1).Sintering raw material preparation stage consists of the steps such as uniform mixing of raw material in storage, and processing, batching, mixing, granulation, and distribution of flux and fuel.

获取价格

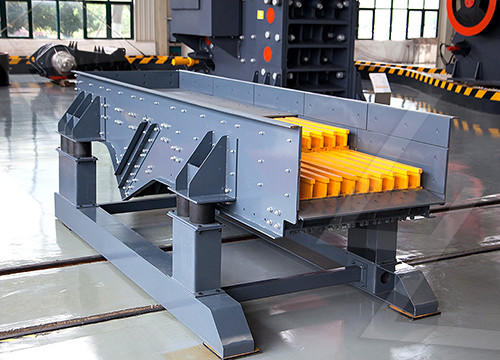

Process Flow Chart – Universal Sintered Products Machinery

Process Flow Chart. ... Our mechanical and hydraulic press equipment can make a wide range of part sizes and shapes. Our hydraulic presses are fully automatic specially designed with press to size type of products it means wire is being fixed in the molding stage which can give the strength of the wire with high load capacity and avoid ...

获取价格

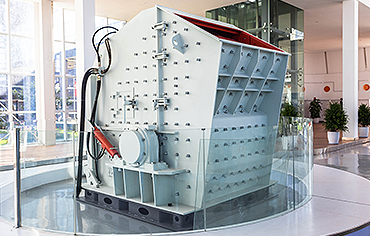

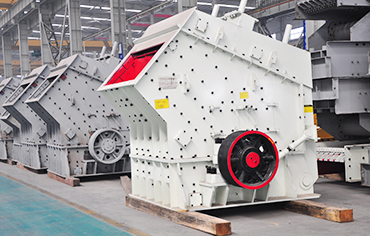

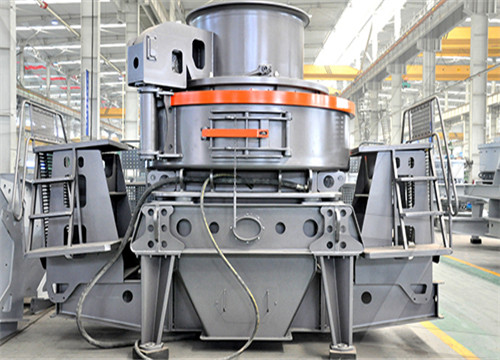

Sintering Process Equipment Used in Iron and Steel

High-quality iron ore sintering process is ensured with advanced equipment from Thermo Scientific for all aspects of iron and steel production and manufacturing. ... Sintering Process Equipment Used in Iron and Steel Manufacturing. ... Flow measurement systems provide continuous, real-time flow measurement of free-falling materials or dense ...

获取价格

The cold sintering process: A review on processing features ...

2021/12/1 The cold sintering process: A review on processing features, densification mechanisms and perspectives ... The equipment needed for cold sintering technique is relatively easy and simple but at this early stage, ... plastic deformation and viscous flow [29, 28]. Dissolution-precipitation within pressure-solution creep is recognized as the main ...

获取价格

Process flow diagram of pelletization unit - ResearchGate

Download scientific diagram Process flow diagram of pelletization unit from publication: Techno-economic Evaluation of Iron Ore Pellet Manufacturing Processes in India and Justification for new ...

获取价格

New Measurement Techniques Describing the Sinter Process

2024/2/15 Steel making using the integrated blast furnace (BF) process route is still the dominant steel production method covering 70% of worldwide steel production and iron ore sintering is one of the most important iron sources within this process, which represent 70–80% of charged iron-bearing materials into modern BF [].Inside this route, sinter plants offer unique

获取价格

Process Flow Diagram Of Sinter Plant - bretagnecolombophilie

The Manganese Ore Processing Plant. Crushing and Sampling of Manganese Rock. ... Process Flow Diagram of Sinter Plant -2 4 Figure-1 Process flow diagram of sintering plant -2 . ... Then according to the requirements for chemical composition of sinter imposed by the ironmaking process, a uniform mixing equipment is used to take and mix the ...

获取价格

Sintering plant at a glance PPT - SlideShare

2014/10/27 This document provides information about the sintering process used in iron and steelmaking. It defines sintering as the agglomeration of iron ore fines into a porous mass through controlled combustion. ... DISC FEEDER SINTER MACHINE PROCESS FLOW WATER WATER H/S RAW MIX 14. 14 Sinter Machine Specification for each machine There are three ...

获取价格

Research on selective laser sintering process of ternary composite ...

2023/8/1 Selective laser sintering experiments are carried out using pulsed fiber laser processing equipment with a galvanometer scanning system. The pulsed fiber laser wavelength λ is 1064 nm, the maximum output average power is 100 W, the focal spot diameter is 28 µm, and the pulse repetition rate is adjustable from 10 to 1000 kHz.

获取价格

(PDF) An Improved Process for Solving the Sintering

3 之 An Improved Process for Solving the Sintering Problem of Al-Si Alloy Powder Metallurgy Hexin Tian † , Fachang Zhao † , Dongmei Ma , Xingming Zhao * , Jingran Meng, Guangan Zhang and Fufa Wu *

获取价格

Sintering process with gaseous fuel injection into the ... - Springer

2024/6/10 This paper presents the results of laboratory experiments to study the effect of the consumption of gaseous fuel (natural gas) supplied into a sintered charge layer on sintering process indicators and sinter quality under the charge conditions of the Ural Steel Company at charge layer heights of 350 to 500 mm.It was established that an increase in the consumption

获取价格