أرسل لنا رسالة

Onsite production process of putty powder

Putty Powder Complete Production Line - Siehe Industry

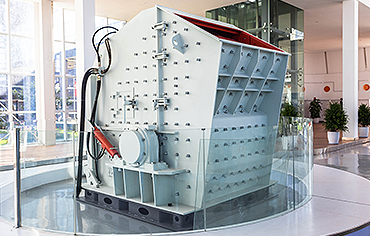

Product Advantages. Highly Professional. Siehe Industry has a wealth of experience in putty powder production and a wide range of line including all needed equipment of putty powder processing; the complete production line

获取价格

Wall Putty Manufacturing Machine Production Process

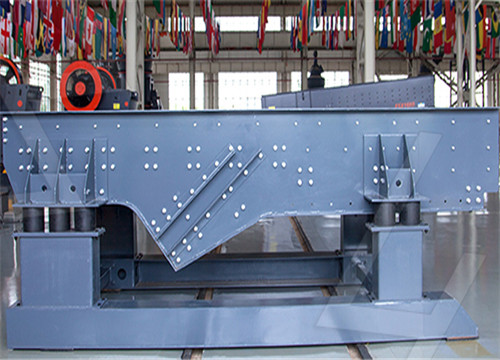

Raw Materialstorage Silo of Wall Putty Manufacturing MachineBatching Bin of Wall Putty Manufacturing MachineWall Putty Mixing MachineAutomatic Packing MachineDust CollectorConveying SystemWall putty manufacturing machine is used to store bulk raw materials, generally using tank design, using tanker truck loading. Only 2 small tanks are needed for the storage of raw materials. The silo is used for storing small quantities of raw materials, such as rubber powder, auxiliaries, etc.在mortarplant上

Putty Powder Manufacturing Process JCT Machinery

2024/1/2 Putty powder raw materials are accurately weighed according to the formulation. They are then mixed together in specific proportions in a mixer. The mixing process ensures a homogeneous blend of all the ingredients. 3.

获取价格

Wall Putty Manufacturing Plant - Decoration For Exterior And

Putty Powder Vertical Mill Production Line Site

The putty powder production process is as follows: The raw materials are weighed and added to the raw material bin. The raw materials are conveyed to the vertical mill. The vertical mill grinds the raw materials into a fine powder.

获取价格

Putty Manufacturing Process Workflow With Lean

Putty Manufacturing Process: The main ingredients of Putty are white cement dolomite in ideal proportion. Normally, the recipe proportion is 1:4 of white cement to dolomite. For example, 5 Tonnes of Putty will have 1 ton of white cement

获取价格

Putty Production Complete Set - Siehe Industry

Putty production process is divided into the following parts: conveying, batching measuring, mixing, conveying, packing and so on; Material conveying: liquid conveying pump and flow meter to realize conveying; Medium and small

获取价格

Putty Powder Complete Production Line - Siehe Group Co.,Ltd.

Siehe Industry has a wealth of experience in putty powder production, provides complete equipment and contracting services for enterprises home and abroad. The putty powder

获取价格

Workflow Of The Putty Manufacturing Process - Master

The fundamental manufacturing process is broken down into four steps: Unloading and storing raw materials. Ingredient weighing or batching. Transmission of raw materials to charging hoppers. blending and combining.

获取价格

Processus de fabrication de poudre de mastic Machines JCT

2024/1/2 Processus de production de poudre de mastic 1. Préparation des matières premières. Carbonate de calcium (CaCO₃) : Il sert de charge principale dans la poudre de mastic. Talc : Ajoute de la douceur au mastic. Ciment blanc : Fournit des propriétés liantes.

获取价格

Putty powder material automatic packaging production line

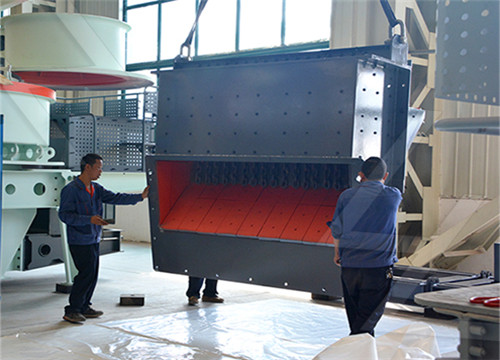

2024/10/16 The overall product packaging line uses AGILOR's high palletizer, no bracket film, and some related supporting systems. Fully automated equipment, strictly control the accuracy and stability of the packaging machine, can be the putty powder according to a certain weight or volume for packaging, and sealing operation to ensure the quality of the product and

获取价格

Wall Putty Manufacturing Plant: How Should You

2024/5/21 What is Wall Putty? Before delving into the production and costs associated with a wall putty manufacturing plant, let’s first understand what wall putty is and its benefits. Wall putty is a fine powder made from white cement,

获取价格

Putty Powder Complete Production Line - Siehe Group Co.,Ltd.

Siehe Industry has a wealth of experience in putty powder production, provides complete equipment and contracting services for enterprises home and abroad. ... 1 Choose different mixer according to material and process requirement; 2 Temperature control, pressure control and other non-standard functions for option: Packing System: Packing: Top ...

获取价格

Wall Putty, Painter's Putty, Wall Care Putty, Ideal for ... - SlideShare

2016/8/20 2. entrepreneurindia.co Wall Putty is white cement mineral based putty for use on cement concrete - mortar interior/exterior walls for smoother stronger adhesion and best suited to minimize paint cost and extend its durability. It is white cement based fine powder which provides an ideal finishing for concrete/cement plastered walls and ceiling.

获取价格

Putty Powder Vertical Mill Production Line Site

The putty powder production process is as follows: The raw materials are weighed and added to the raw material bin. The raw materials are conveyed to the vertical mill. The vertical mill grinds the raw materials into a fine powder. The cyclone separator separates the coarse particles from the fine powder.

获取价格

Wall Putty: Types, Process, Importance, Benefits, Application,

Gypsum-based Wall Putty: Gypsum powder serves as the main component in the formulation of gypsum-based wall putty. High whiteness, a great surface polish, and outstanding water resistance are all provided. ... This can entail using recycled materials, bio-based additives, and reducing the production process’ carbon impact. Improved Crack ...

获取价格

CN103408987A - Method for preparing putty powder from waste

The invention discloses a method for preparing putty powder from waste residue generated in production process of calcium carbonate and the prepared putty powder, wherein the waste residue generated in the production process of calcium carbonate can be adequately utilized, thus increasing the utilization value of the waste residue; and the finally prepared putty powder is

获取价格

Dry mix mortar production line manufacturer- Qingchi Tech

Qingdao Qingchi Intelligent Technology Co., Ltd. is an industrial company engaged in the design, research, processing, manufacturing and sales services of dry-mixed (powder) mortar production lines, special mortar production equipment, putty powder production lines, gypsum mortar equipment, and mortar construction equipment.. The company focuses on scientific and

获取价格

Waterproof Wall Putty: What You Need to Know Before Applying It

2024/10/30 Formula 1: Interior Wall Waterproof Putty Powder (per ton addition in kg) – Gray calcium (325~400 mesh): 250 kg – Heavy calcium (325~400 mesh): 750 kg – HPMC additive: 3.5 kg – PVA: 1~3 kg – Bentonite: 20~40 kg . Formula 2: Interior Wall Waterproof Putty Powder (per ton addition in kg) – Gray calcium (600 mesh): 400 kg

获取价格

Dry mix mortar plant manufactuer-Top 4 manufactured in China

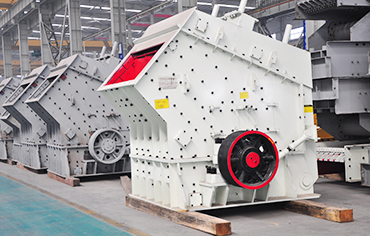

We are dry mix mortar plant manufacturer, dry mix mortar plant supplier,Wall Putty Manufacturing Machine manufacturer,Wall Putty Manufacturing Machine supplier,Various dry mortar production lines, wall putty powder production equipment, including belt mixers, plow-shear mixers, sand dryers, cement silos, screw conveyors, belt conveyors, pneumatic conveyors,

获取价格

Wall Putty Making Machine Top 10 Manufacturer In China

So the whole wall putty making machine needs 2 workers. We use 3 ribbon putty mixing machines, mixing uniformity can reach 99.8%. We also designed an observation port on the wall putty making machine for you. When mixing for about five minutes, you can sample and observe the uniformity of the material to find out the best mixing time.

获取价格

CN114621624A - Production process of green environment

The invention discloses a production process of green environment-friendly multifunctional putty powder, belonging to the technical field of putty powder production processes, and the putty powder is prepared from the following raw materials in parts by weight: 20-50 parts of base material, 500-1000 parts of filler, 10-40 parts of water and 20-50 parts of auxiliary agent.

获取价格

SIEHE Waterborne putty production line successfully put

2024/9/3 The putty production process is divided into material conveying, measuring, mixing, filling and packaging. *Material conveying and measuring are divided into powder and liquid modules. The powder 1 are unpacked by the ton bag unpacking feeding station, delivered to the bin by the bucket elevator, and then fed by the conveying screw.

获取价格

Dry mix mortar plant manufactuer-Top 4 manufactured

We are dry mix mortar plant manufacturer, dry mix mortar plant supplier,Wall Putty Manufacturing Machine manufacturer,Wall Putty Manufacturing Machine supplier,Various dry mortar production lines, wall putty powder production

获取价格

Wall Putty Making Machine Top 10 Manufacturer In

So the whole wall putty making machine needs 2 workers. We use 3 ribbon putty mixing machines, mixing uniformity can reach 99.8%. We also designed an observation port on the wall putty making machine for you. When mixing for

获取价格

CN114621624A - Production process of green environment

The invention discloses a production process of green environment-friendly multifunctional putty powder, belonging to the technical field of putty powder production processes, and the putty powder is prepared from the following raw materials in parts by weight: 20-50 parts of base material, 500-1000 parts of filler, 10-40 parts of water and 20-50 parts of auxiliary agent.

获取价格

SIEHE Waterborne putty production line successfully put

2024/9/3 The putty production process is divided into material conveying, measuring, mixing, filling and packaging. *Material conveying and measuring are divided into powder and liquid modules. The powder 1 are unpacked by the ton bag unpacking feeding station, delivered to the bin by the bucket elevator, and then fed by the conveying screw.

获取价格

Dry mixed mortar production line, putty powder production line ...

Wuxi Fengdu Industrial Technology Co., Ltd. specializes in equipment such as dry mixed mortar production lines, putty powder production lines, and concrete mixers! Contact information: 13585018212

获取价格

Putty Powder Manufacturing Process JCT Machinery

2024/1/2 Putty powder raw materials are accurately weighed according to the formulation. They are then mixed together in specific proportions in a mixer. The mixing process ensures a homogeneous blend of all the ingredients. 3. Wet Grinding. The mixed putty powder raw materials are subjected to wet grinding. This involves using water to create a slurry.

获取价格

Wall Putty Production Batching Mixing Plant Automatic Dry Powder

Wall Putty Production Batching Mixing Plant Automatic Dry Powder Cement Masonry Gypsum Plaster Premix Mortar Concrete Mix Tile Adhesive, Find Details and Price about Dry Mortar Plant Dry Power Production Line from Wall Putty Production Batching Mixing Plant Automatic Dry Powder Cement Masonry Gypsum Plaster Premix Mortar Concrete Mix Tile Adhesive -

获取价格

Internal wall putty and production process thereof

2018/11/30 The invention belongs to the technical field of building materials, and particularly relates to an internal wall putty which comprises the following components in parts by weight: 150-300 parts of white cement, 500-900 parts of calcium carbonate powder, 10-50 parts of grey desert soil, 1-8 parts of cellulose ether, 7-30 parts of polymer latex powder, 1-10 parts of

获取价格

What is Wall Putty Powder? - Hebei XingMu Machinery Co., Ltd.

2024/4/25 Wall putty is an important supporting material used in the coating process. It is closely related to the use of paint and has an important influence on the quality of paint projects. The purpose of applying wall putty in the coating project is mainly to improve the decorative effect or to produce a functional effect. The negative []

获取价格

SIEHE Waterborne putty production line successfully put

2024/9/3 The putty production process is divided into material conveying, measuring, mixing, filling and packaging. *Material conveying and measuring are divided into powder and liquid modules. The powder 1 are unpacked by the ton bag unpacking feeding station, delivered to the bin by the bucket elevator, and then fed by the conveying screw.

获取价格

Interior wall putty powder-Suzhou LONZONE New Material

Interior wall putty powder This product is made of excellent inorganic gelling materials and refined fillers as the main base materials, and is compounded with a variety of imported additives through a unique production process. It can be used by adding water and stirring on site. It is an interior wall leveling putty that is easy to construct, good to polish, and has high bonding strength.

获取价格

The reason why the cellulose production putty powder foams

2024/6/30 The Chemical Reactions Behind Cellulose Production Putty Powder FoamingCellulose production putty powder is a commonly used material in various industries, including construction and manufacturing. It is known for its ability to create a smooth and even surface when applied to walls or other surfaces. However, one peculiar characteristic of this

获取价格

Putty Powder Complete Production Line - m.sieheindustry

Siehe Industry has a wealth of experience in putty powder production and a wide range of line including all needed equipment of putty powder processing; the complete production line mainly consists of raw material storage, conveying and batching equipment, mixing equipment, finished products storage, sieving, demagnetization, packing and dust ...

获取价格

Customized Dry Mortar Mixer Tower Putty Powder Mixing

The special mortar production line can produce dozens of special mortars such as waterproof mortar, thermal insulation mortar, color mortar, anti-crack mortar, sound insulation mortar, shield mortar, tile glue, and so on. The process layout is reasonable, the structure is compact, and the production process adopts automatic control.

获取价格